We have seen from one of my previous post titled

‘Composite fuel briquettes : Converting agricultural

waste (Bagasse) into Charcoal’ and

my blog on sdsanbhatshareslearnings.blogspot.com that any agricultural wastes

would be unsuitable to be used directly in as is available form on account of

serious health and environmental problems ensuing thereof. It needs to be

converted into a solid or liquid form for its efficient use. In this post we learn on one such traditional agricultural waste i.e. bagasse and decide

on the need to unlearn/relearn the same as regards its suitability today as an

alternative fuel.

Abstract

We attempt to learn through somewhat of an extensive online literature/statistical survey on bagasse based on;

Abstract

We attempt to learn through somewhat of an extensive online literature/statistical survey on bagasse based on;

o

Properties:

In order that the agricultural waste like bagasse could be used as an

alternative fuel, one needs to firstly ascertain their comparative value in terms of

dry heat content availability with the commonly used commercial fuel forms of coal,

petrol, LPG, etc.

o

Availability: In

order that the agricultural waste could be used as an alternative fuel, one needs

to ascertain not just in the sense of numbers or tons availability but something

beyond it too.

In this technical post, we therefore conclusively intend

to ascertain the true nature of agricultural wastes such as bagasse as an alternative fuel but also to them being really

a renewable energy source while probing at that 'something beyond' aspect mentioned above.

Introduction

What

is BAGASSE?

Sugarcane has been a seasonally-grown food

and feed crop, the processing of which creates bagasse, a low-cost biomass material,

as its by-product. Bagasse is a commodity that is readily available for use — since

2002, more than 610 million tons of bagasse was produced worldwide. It is

suitable for production of energy, ethanol, animal feeds, paper products,

composite board, and building materials; and it is a feed stock for fluidized -

bed production of a range of chemicals.

Selection

of biomass and waste as an alternative fuel

Renewable

Energy Program- Govt. of INDIA

Since

the

availability of fossil fuel has been on the decline and use of the same

inflating the adverse impact on environment and ecology, the conception of

bagasse combustion as a sole means of

solid waste disposal has changed. Therefore in this

backdrop the norms for renewable sources of energy (RSE) were

given importance not only in India but has attracted the global attention.

The

main items under RSE are as follows:

i)

Hydro Power

ii)

Solar Power

iii)

Wind Power

iv)

Bio-mass Power

v)

Energy from waste

vi)

Ocean energy

vii)

Alternative fuel for surface transportation

Discussion

A. Properties

Physical

properties;

1.

White & light green.

2.

It is odourless.

3.

The typical specific weight is 250 Kg/m3.

4.

The main content: - 45% moisture, 50%

cellulose - (27.9% hemi cellulose, 9.8% lignin & 11.3% cell contents) &

6% others.

5.

Energy content: - 19400 KJ/Kg dry ash free.

Chemical properties;

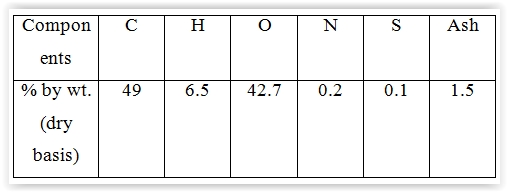

The percentage distribution by dry wt. of

major elements composing the bagasse is present in the below table.

Chemical formula: Estimation of the chemical formula of

bagasse;

1)The

percentage distribution of the elements with & without the water contained:

Given:

- 100 Kg bagasse based on 45% of moisture content.

2)Computering the molar composition of the elements neglecting the ash component:

3)Setting up the computation table to determine the normalized mole ratio:

4)

Approximate

chemical formula of bagasse:

Without water : - C1125H1800O735N4S

With water : - C1125H4250O1985N4S

Bagasses are the fibrous residue of the cane

stalks after crushing & consist mainly of cellulose, pentosans &

lignin. Its final composition after milling depends on method of harvesting as

well as age & type of cane. On average it is assumed to have 50% moisture,

47.7% fibre & 2.3% soluble solids.

B. Overview of sugar industries

Dry matter productivity of some selected

agricultural crop;

Sugarcane bagasse has been reported to

contain 48% cellulose. It thus implies that the total world production of

233.942 million tons of bagasse from 15,895 hectares would yield 112.29 million

tons of cellulose. These data indicate that based on per unit of land area

sugarcane was the most productive cellulose producing crop. The majority of

bagasse produced in small or large scale factories has been generally used as

fuel in the same factory where it was produced to generate steam & electricity.

Sugar industries scenario in INDIA;

Sugar industry has been the second largest industry after

textile in India. India also stands among the first five countries of sugar

production in the world. The annual turnover of the sugar industry has been

around 5500 crores of rupees and the total investment is around 3500 crores of

rupees. It also employs directly or indirectly of about 1.75 crores people in

India as is evident from the crushing capacity of sugar mills that vary from about 1500 - 5000

tonnes per day. Sugar cane synthesis the maximum solar residue and energy

into biomass like sugar, cellulose, lignin and pentosans.

Profile of Indian sugar Industry;

The sugar companies comes under the Board of

Industrial & Financial Reconstruction (BIFR). As per the information

provided by the BIFR as on 30-06-2003, 44 companies involving 76 sugar mills were registered with BIFR.

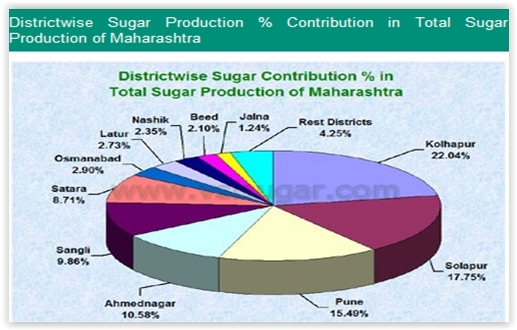

Some more overview of the sugar industries are presented as shown below:

- Sugar Statistics – India

•

Sugar Statistics – Maharashtra

Maharashtra sugar industry at a glance

•

Sugar Statistics – World

Bagasse production

(most recent) by country

Conclusion

Total bagasse

estimated production in the world (Year 2005) : 407,213,347 tons

Based on the above

available figure the amount of bagasse that could be channeled as an renewable

source of energy is tremendous as seen from the below comparison.

High Calorific Value (HCV) or Gross Calorific Value (GCV) of coal is 15000 – 27000 KJ/KG

HCV or GCV of dry ash free bagasse is 19400

KJ/ Kg

HCV or GCV of fuel oil is 41200 KJ/L

HCV or GCV of LPG is 94000 KJ/M³

1 ton of bagasse =

1 barrel of fuel oil = 0.173 ton of fuel

oil

1 tonne LPG = 8.46

barrels of fuel oil equivalent = 8.46

tonnes of bagasse

1 ton coal = 3.4

tons bagasse

The current price

of Indian coal is $22-23 (approximately Rs.1250 ) a tonne

Bagasse is worth

between Rs.690 and Rs.725 per tonne (mill-run weight, 50 percent moisture

content) and a figure of Rs.750 could be used as a rounded representative average

LPG at Rs.24000

per tonne

Fuel oil is rated

at Rs.3500 per barrel

One kg of coal can

generate approximately 8kg of steam

Approximately 15

kg of steam can be produced from 1 kg of oil, or 14 kg of steam from 1 litre of

oil

Approximately 42

kg of steam can be produced from 1 Therm of gas i.e. Natural gas & Liquefied petroleum gases (LPG)

1 ton of coal can

generate about 1500 kwh of electricity

1 barrel of fuel

oil can generate about 1700 kwh of electricity or one gallon of crude oil can

produce about 17 kWh

1 ton cane

crushing can produce 100 KwH of electricity where one ton of sugarcane, yields

about 250 kg of bagasse

1 therm of natural

gas = 29.3 kWh of electricity where 1therm = 100 cubic feet = 2.265 kg

For the next post, let us delve into the 'something beyond factor' i.e.

the procurement

cost feasibility for bagasse (as also other agricultural wastes too) as highlighted below without which the practicality of being

renewable would be only on paper inspite of them having good properties and tons in

availability.

1. The localized availability aspect in

comparison with the commercial fuels’ centralized mining/production

2. The availability aspect in comparison with

the commercial fuels’ excellent transportation and distribution channels post

mining/production

3. The sustained availability in terms of

renewable in nature i.e. could it offset the inherent excellent properties of

the commercial fuels and their centralized mining/production systems?

References

[1]

D.S Chahal. “Food, Feed & Fuel from Biomass”, reprint 1991, pp.23.

[2]

N.H. Ravindranath, K. Usha Rao, Bhaskar Natranjan. “Renewable Energy & Environment”, 2nd

reprint 2000 pp.106, 242.

[3]

L.A Ekal, S.H Pawar. “Advances in renewable energy technologies”, 1st reprint

pp.35, 194.

[4]

S. Rao, Dr. B.B. Parulekar. “Energy Technology”, 2nd edition,

1997.

[5]

G.D Rai. “Energy Resources”, 3rd edition, 1999.

[6]

http://164.100.24.208/Is/committeeR/Food/27.pdf

[7]

http://bioproductsbioenergy.gov/pdfs/bcota/abstracts/30/z130.pdf

[8]

http:// Polystyrene#Environmental impact

[9] www.springerlink.com/index/232k30g002472824.pdf

[10]

http://www.vsisugar.com

Amazing post Exploring Bagasse s Sustainable Alternative Fuel Source. Learn how this eco-friendly material is revolutionizing energy production and reducing environmental impact. Thanks for sharing.

ReplyDeleteBagasse Plates Manufacturer in India

Cool

ReplyDeleteGreat perspective on bagasse as fuel! Agarwal Machineries, a sugarcane bagasse tableware making machine manufacturer, values such innovative uses of agro-waste for both energy and eco-products. Sustainable thinking!

ReplyDelete